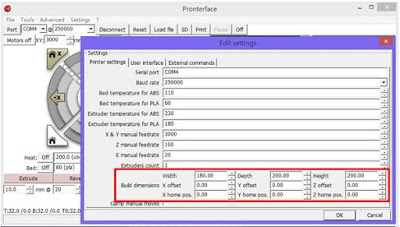

Here is the setting for my Pronterface.

After couple hours of trial and error, here are my findings and solution to the problem.

In Slic3r, when the origin of the print bed is set to the center - in this case, X: 90, Y: 100 (see below photo) and the setting is written into the configuration file, the bed shape setting in the configuration file is "bed_shape = -90x-100,90x-100,90x100,-90x100" (see the next photo).

When the origin of the print bed is set to the bottom left corner - in this case, X: 0, Y: 0 (see below photo), the bed shape setting in the configuration file is "bed_shape = 0x0,180x0,180x200,0x200 (see the next photo).

Note,

1. Simply changing the X & Y values in the Bed Shape window and clicking the save button under "Printer Setting" won't write the setting into the configuration file. To write the new setting into the configuration file, select "Export Config.." under the File pull down menu.

2. The "Export G-code.." command can be performed immediately after the X & Y values in the Bed Shape window are changed and the Gcode generated will be based on the latest X & Y values.

With the origin set to X: 0, Y: 0 in Slic3r, the sliced model is now placed in the center of the print bed (see below photo).

It's worth to note that in Kisslicer, if the object is to be placed in the center of the print bed, the configuration is like the one shown in the red box in the photo below.

--------------------------------------------------------------------------------------------------------------------------

For the Twisted Spiral Vase, here are the settings in my Slic3r configuration file (config_18x20_PETG_E3D_160323.ini).

avoid_crossing_perimeters = 0

bed_shape = 0x0,180x0,180x200,0x200

bed_temperature = 0

before_layer_gcode =

bottom_solid_layers = 3

bridge_acceleration = 0

bridge_fan_speed = 100

bridge_flow_ratio = 1

bridge_speed = 60

brim_width = 0

complete_objects = 0

cooling = 1

default_acceleration = 0

disable_fan_first_layers = 3

dont_support_bridges = 1

duplicate_distance = 6

end_gcode = M104 S0 ; turn off temperature\nG28 X0 ; home X axis\nG28 Y0 ; home Y axis\nM84 ; disable motors\n

external_fill_pattern = rectilinear

external_perimeter_extrusion_width = 0

external_perimeter_speed = 50%

external_perimeters_first = 0

extra_perimeters = 1

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0

fan_always_on = 0

fan_below_layer_time = 60

filament_colour = #FFFFFF

filament_diameter = 2.93

fill_angle = 45

fill_density = 0%

fill_pattern = honeycomb

first_layer_acceleration = 0

first_layer_bed_temperature = 0

first_layer_extrusion_width = 200%

first_layer_height = 0.35

first_layer_speed = 30

first_layer_temperature = 165

gap_fill_speed = 20

gcode_arcs = 0

gcode_comments = 0

gcode_flavor = reprap

infill_acceleration = 0

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 15%

infill_speed = 80

interface_shells = 0

layer_gcode =

layer_height = 0.3

max_fan_speed = 100

max_print_speed = 80

max_volumetric_speed = 0

min_fan_speed = 35

min_print_speed = 10

min_skirt_length = 0

notes =

nozzle_diameter = 0.4

octoprint_apikey =

octoprint_host =

only_retract_when_crossing_perimeters = 1

ooze_prevention = 0

output_filename_format = [input_filename_base].gcode

overhangs = 1

perimeter_acceleration = 0

perimeter_extruder = 1

perimeter_extrusion_width = 0

perimeter_speed = 60

perimeters = 1

post_process =

pressure_advance = 0

raft_layers = 0

resolution = 0

retract_before_travel = 2

retract_layer_change = 0

retract_length = 2

retract_length_toolchange = 10

retract_lift = 0

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 40

seam_position = aligned

skirt_distance = 6

skirt_height = 1

skirts = 1

slowdown_below_layer_time = 5

small_perimeter_speed = 15

solid_infill_below_area = 70

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0

solid_infill_speed = 20

spiral_vase = 1

standby_temperature_delta = -5

start_gcode = \n

support_material = 0

support_material_angle = 0

support_material_contact_distance = 0.2

support_material_enforce_layers = 0

support_material_extruder = 1

support_material_extrusion_width = 0

support_material_interface_extruder = 1

support_material_interface_layers = 3

support_material_interface_spacing = 0

support_material_interface_speed = 100%

support_material_pattern = pillars

support_material_spacing = 2.5

support_material_speed = 60

support_material_threshold = 0

temperature = 165

thin_walls = 1

threads = 2

toolchange_gcode =

top_infill_extrusion_width = 0

top_solid_infill_speed = 15

top_solid_layers = 0

travel_speed = 130

use_firmware_retraction = 0

use_relative_e_distances = 0

use_volumetric_e = 0

vibration_limit = 0

wipe = 0

xy_size_compensation = 0

z_offset = 0

No comments:

Post a Comment